Product Description

Using optical fibers as the sensing medium, it is possible to remotely and real-time monitor the temperature of objects along the optical fiber route, which is a new technology for real-time measurement of spatial temperature field distribution. It can continuously measure the temperature along the optical fiber route, with a measurement distance of up to tens of kilometers, and has the advantages of high precision, non-electricity, resistance to RF and electromagnetic interference, fireproof, explosion-proof, corrosion resistance, high pressure and strong electromagnetic field resistance, radiation resistance, fast data transmission and reading speed, good self-adaptability, and precise positioning. It can work in various harsh environments and can be widely used in temperature monitoring and disaster warning in industrial sites such as offshore wind power, drilling platforms, power generation, petrochemical, transportation, metallurgy, etc.

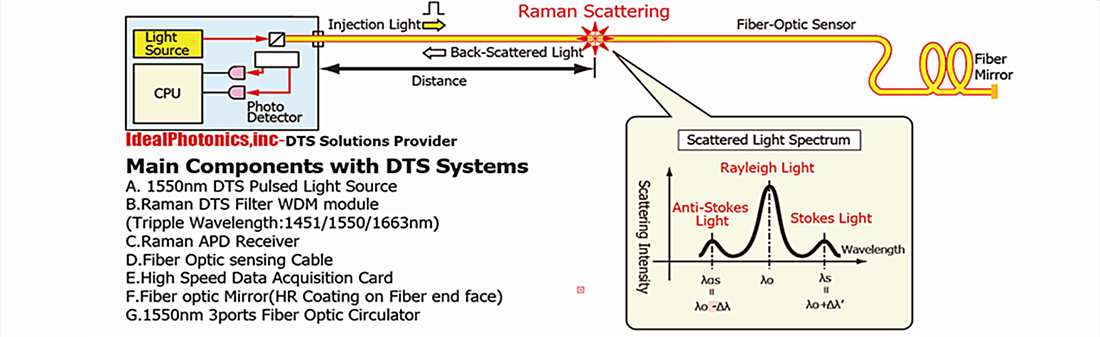

Technical Principle

Distributed Temperature Sensing (DTS) detects the temperature changes at different positions along the optical fiber based on the temperature effect of optical time domain reflectometry (OTDR) and fiber Raman scattering, thus achieving truly distributed measurement.

In the system, optical fiber is both a transmission medium and a sensing medium. The temperature field at each point in the space where the optical fiber is located modulates the intensity of the Raman scattered light in the optic

Key Features:

Ø In the distributed optical fiber temperature measurement system, the optical cable is both a temperature sensor and a signal transmission channel, and no other measurement or transmission devices are required.

Ø Support long-distance monitoring, can cover a wide area, to achieve distributed, real-time temperature monitoring.

Ø Distributed temperature detection, high temperature measurement accuracy, high positioning accuracy.

Ø Distributed temperature detection, continuous monitoring without blind spots.

Ø 24 hours real-time online monitoring, truly unattended.

Ø Fiber break fault alarm and accurate positioning, easy maintenance

Application Scenarios:

Ø Power Industry: power cable temperature monitoring, thermal management of distribution cabinets and battery packs, and overheating warning of large transformers.

Ø Energy and Industry: Oil and gas pipeline leak detection, power line temperature monitoring, and nuclear power facility safety monitoring.

Ø Petroleum and petrochemical: temperature monitoring in dangerous areas of oil and gas pipelines and storage tank areas.

Ø Coal mine: underground belt conveyor and tunnel temperature monitoring.

Ø Transportation: tunnel fire warning, subway station environmental monitoring, airport runway temperature monitoring.

Ø Infrastructure: long-distance pipeline leakage prevention monitoring and bridge structure health diagnosis.

Specifications

|

Model |

STI-R10 |

STI-R25 |

|

≥10 |

≥25 |

|

|

1/2/4/8 channel |

||

|

Fiber Type |

SM/MM |

|

|

Connector |

FC/APC |

|

|

Measurement Wavelengths (nm) |

1550 |

|

|

Positioning Accuracy |

±1m |

|

|

Temperature Detecting Range |

-20℃ to +120℃ |

|

|

Temperature Resolution |

0.1℃ |

|

|

±1℃ |

±1.5℃ |

|

|

Spatial Resolution |

5 meters |

|

|

Response Time |

≤ 10 seconds |

|

|

Measurement Time (Full Scan) |

≤ 2 minutes |

≤ 15minutes |

|

Measurement Parameter |

Temperature |

|

|

Communication Interface |

Ethernet Port, USB |

|

|

Working Temperature |

-10℃ to +40℃ |

|

|

Operating Humidity |

0~95% Relative Humidity (Non-condensing) |

|

|

Storage Temperature |

-20℃ to +70℃ |

|

|

Power Supply |

220V/AC 50Hz |

|